Box build assembly has become an essential part of modern electronics manufacturing, offering a complete and streamlined approach for assembling finished electronic products. Instead of focusing only on the PCB level, box build assembly covers everything from wiring, enclosures, subassemblies, and cable harnesses to full system integration. As today’s industries demand faster production, higher accuracy, and greater reliability, box build assembly provides a unified manufacturing solution that ensures consistent quality and smooth project execution from start to finish.

Understanding Box Build Assembly

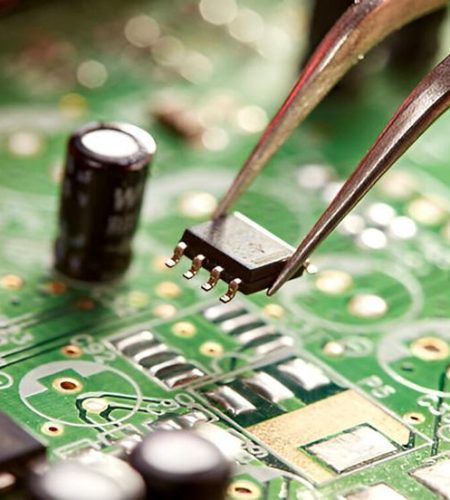

Box build assembly represents the final stage of electronic product manufacturing. It involves assembling the electronic components, PCBs, mechanical parts, wiring systems, and enclosures into a complete and functional unit. Unlike PCB assembly, which focuses solely on populating components onto printed circuit boards, box build assembly integrates those assembled boards with other elements to produce a ready-to-use device. This complete approach is especially important for industries such as telecommunications, medical devices, aerospace, industrial automation, consumer electronics, and automotive systems, where reliability and precision are non-negotiable.

What Makes Box Build Assembly Unique

The most significant aspect of box build assembly is the level of customization it supports. Every product has unique physical, electrical, and environmental requirements, making assembly processes different for each project. Whether the product requires a metal or plastic enclosure, complex wiring, thermal management, or multi-board integration, box build assembly ensures that every piece fits and functions together seamlessly. Manufacturers rely on detailed specifications, wiring diagrams, BOMs, and 3D models to execute builds accurately and efficiently.

Key Elements of Box Build Assembly

Box build assembly includes several interconnected stages that bring the final product to life. It starts with the preparation of subassemblies, which often includes SMT or through-hole assembled PCBs, cable harnesses, and molded plastics. These components are inspected individually to ensure quality before moving to the main assembly stage.

Integration, Wiring, and Enclosure Assembly

During integration, technicians mount PCBs into the enclosure, install internal hardware, and carefully route cables and wiring harnesses. Proper cable management is crucial because it prevents signal interference, overheating, and mechanical wear. The enclosure assembly phase involves adding external components such as switches, connectors, screens, or thermal interfaces. Depending on the product, additional steps like installing gaskets, adhesives, safety components, or insulation materials may also be required to ensure the device meets compliance standards.

Testing in Box Build Assembly

Testing is a vital part of box build assembly because it confirms that the final product functions correctly before delivery. Manufacturers perform functional testing, electrical safety testing, burn-in testing, and environmental testing depending on the application. These evaluations reveal any performance issues that may not be detectable during earlier stages of PCB-level inspection.

Ensuring Reliability and Performance

The goal of testing is to verify the product’s durability, stability, and long-term performance. Complex devices may require software installation, firmware programming, calibration, or communication testing. In sectors like medical and aerospace, reliability is critical, so manufacturers follow strict protocols and documentation to certify that every assembled unit is ready for real-world operation. This attention to detail ensures that box build assembly results in products that meet industry standards and stringent customer requirements.

Why Industries Depend on Box Build Assembly

Industries choose box build assembly because it provides a complete solution that saves time, simplifies production, and reduces operational stress. Instead of managing multiple vendors for PCB assembly, cable production, mechanical fabrication, and enclosure assembly, companies rely on a single partner to deliver fully integrated products. This streamlined approach eliminates unnecessary handling, reduces errors, and ensures consistent communication throughout the manufacturing process.

Cost Efficiency and Faster Time-to-Market

By centralizing assembly operations, businesses experience reduced lead times and lower production costs. A unified workflow minimizes supply chain complexity and avoids delays caused by coordination issues. Companies benefit from faster product launches, lower rework rates, and enhanced customer satisfaction. With box build assembly, manufacturers can scale production quickly without compromising quality, making it an attractive choice for startups and large enterprises alike.

The Growing Importance of Box Build Assembly

Box build assembly has become even more important as products evolve and become more advanced. Devices today require greater functionality, tighter tolerances, and compliance with global industry standards. As the complexity of electronic products increases, the demand for precise and efficient box build assembly continues to grow. Manufacturers equipped with advanced tools, skilled technicians, and robust QA systems are able to manage this complexity while delivering reliable, polished, and professionally assembled products.

Supporting Innovation Across Industries

From IoT devices and smart home systems to advanced medical equipment and industrial robotics, box build assembly supports innovation across a wide range of markets. It enables product designers to experiment with new materials, technologies, and layout configurations, knowing that the final assembly can be executed accurately. This collaboration between engineering and manufacturing helps bring ideas to life quickly and effectively.

Choose Expert PCB Assembly Service Providers for High-Quality Box Build Assembly

For businesses seeking a dependable and efficient solution for complete system assembly, partnering with a professional PCB assembly service provider is essential. An experienced partner ensures precision at every stage—from PCB integration and wiring to enclosure assembly and functional testing. By working with experts who understand the full scope of electronics manufacturing, companies can achieve faster production cycles, improved product quality, and a smooth path from concept to market-ready devices.