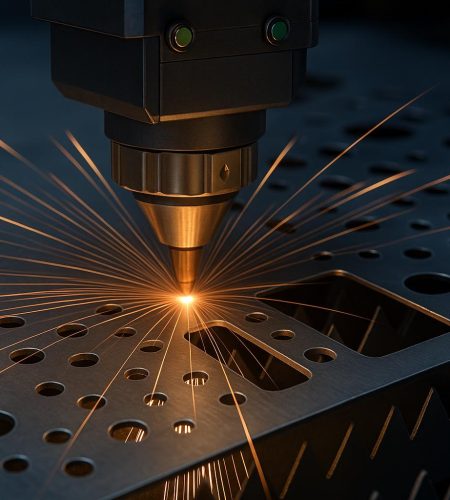

Laser cutting has become a cornerstone of modern metal fabrication, offering unmatched precision, speed, and flexibility across a range of industries. From automotive and aerospace components to architectural structures and custom art installations, the process allows manufacturers to achieve exacting standards of detail and quality. The adoption of advanced laser systems has redefined how metals such as steel, aluminium, and copper are shaped, with minimal waste and consistent results.

Understanding the Laser Cutting Process

Laser cutting uses a focused beam of light to melt, burn, or vaporise material along a designated path. The process is typically controlled by computer numerical control (CNC) systems, allowing for exceptional accuracy even with complex geometries. Depending on the thickness and type of material, different laser sources—such as CO₂, fibre, or Nd:YAG—are selected to optimise cutting quality and efficiency.

One of the most significant benefits of laser cutting lies in its contactless nature. Since there is no physical tool wear or mechanical pressure applied to the material, the risk of distortion or contamination is greatly reduced. This makes it particularly suitable for fine detail work and delicate components where precision is paramount.

Advantages of Stainless Steel Laser Cutting

Stainless steel is one of the most commonly processed metals using laser technology. It offers strength, corrosion resistance, and an attractive finish, making it a preferred choice in industries such as food processing, medical devices, and construction. Laser cutting enhances these qualities by providing clean, burr-free edges and high-quality surface finishes that often require little to no post-processing.

Additionally, stainless steel laser cutting is highly efficient in material usage. The narrow kerf width and precise control allow for tight nesting of parts on a sheet, reducing waste and lowering overall production costs. When combined with automated systems, laser cutting can achieve high-volume throughput without compromising accuracy.

Applications Across Industries

The versatility of laser cutting extends to a wide variety of sectors. In the automotive industry, it enables the creation of lightweight, intricate parts with consistent performance. In architecture and interior design, the technology allows for detailed decorative panels and custom fittings. Meanwhile, in the medical field, the ability to cut fine and precise shapes supports the production of surgical instruments and components that demand exacting standards.

Manufacturers also rely on laser cutting for rapid prototyping. The process can quickly translate digital designs into physical models, facilitating faster design iterations and reducing lead times. This speed and adaptability make laser cutting indispensable in modern manufacturing workflows.

Environmental and Operational Benefits

Beyond precision and efficiency, laser cutting also offers environmental advantages. The process generates minimal waste and requires no lubricants or cutting fluids, making it a cleaner alternative to traditional machining methods. Furthermore, advancements in fibre laser technology have improved energy efficiency, reducing power consumption without sacrificing cutting performance.

Operationally, laser cutting reduces the need for multiple production steps. Traditional fabrication processes often involve cutting, deburring, and finishing as separate stages, whereas laser systems can achieve all of these in a single operation. This streamlining not only saves time but also enhances workplace safety by reducing manual handling and tool changes.

Choosing a Local Laser Cutting Service

Selecting the right laser cutting service is essential to achieving optimal results. Factors such as equipment capability, material expertise, and quality control systems all influence the final outcome. Many companies offer a range of services tailored to specific materials and thicknesses, ensuring that each project is handled with the appropriate technology and skill.

For those searching for stainless steel laser cutting near me, working with an experienced local provider can deliver numerous benefits. Local services often provide faster turnaround times, reduced shipping costs, and greater flexibility for custom requirements or design adjustments. In addition, local collaboration allows for better communication throughout the project, ensuring that specifications are met accurately.

The Future of Laser Cutting Technology

The future of laser cutting continues to evolve with innovations in automation, software integration, and energy efficiency. Artificial intelligence and machine learning are increasingly being used to optimise cutting paths, predict maintenance needs, and enhance productivity. Hybrid systems that combine laser cutting with additive manufacturing or robotic handling are also emerging, enabling greater versatility and efficiency on the shop floor.

As industries continue to demand higher precision and faster production, laser cutting will remain central to advanced manufacturing processes. Its ability to deliver consistent, high-quality results across a wide range of materials ensures that it will continue to be an essential tool in metal fabrication for years to come.

Conclusion

Laser cutting has revolutionised the way metal components are designed and produced. Its precision, speed, and adaptability make it one of the most efficient and reliable fabrication methods available today. From small-scale custom projects to large industrial applications, the technology continues to set new standards in quality and performance. As innovations drive further advancements, laser cutting will remain at the forefront of modern manufacturing, shaping the future of metal fabrication with accuracy and efficiency.