In today’s world, plastic products are ubiquitous, serving a vast array of industries. Behind these versatile products lies a critical component of the production process: plastic extruders. These machines transform raw plastic materials into useful shapes and forms through a process called extrusion. With different types of plastic extruders available, choosing the right one is essential for efficient and high-quality production. This article explores the various types of extruders and how they cater to diverse applications.

Single Screw Extruders

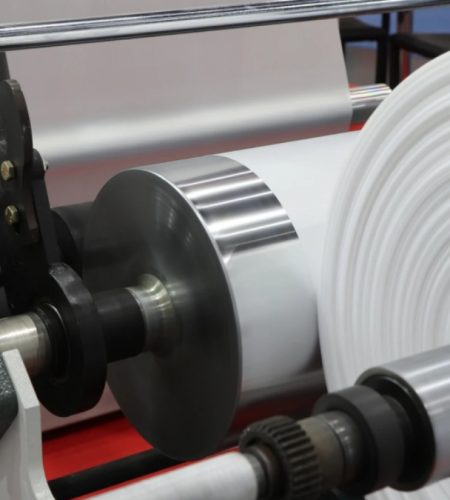

The most common and widely used extruder type is the single screw extruder. As the name suggests, these extruders have a single screw housed in a cylindrical barrel. They are often employed in straightforward processes where uniformity and efficiency are required, such as in the production of pipes, films, and sheets. Single screw extruders are ideal for operations that primarily involve the melting and forming of thermoplastics. Their simplicity makes them cost-effective, easy to operate, and highly reliable. However, they might not be the best option for more complex processes, especially where mixing or compounding of materials is needed.

Twin Screw Extruders

For more complex operations requiring superior mixing capabilities, twin screw extruders are the go-to choice. Equipped with two screws that rotate in tandem (either in the same direction or opposite directions), these extruders excel at blending additives and fillers into plastics. Industries that produce high-performance plastic materials, including those for automotive and packaging applications, often rely on twin screw extruders due to their ability to handle a wide range of polymers and achieve uniform mixing. Their versatility makes them indispensable in applications like compounding, color masterbatch production, and the creation of specialty materials.

Co-Extruders

Many plastic extrusion companies offer co-extruders for products that require multiple layers of different materials. These machines enable the simultaneous extrusion of two or more polymers, allowing to produce multilayered products. Co-extruders are particularly useful in the packaging industry, where multilayer films provide enhanced properties such as improved barrier protection and durability. This technology allows manufacturers to combine different materials without compromising the final product’s integrity, offering flexibility and enhanced functionality in a single product.

Laboratory Extruders

When it comes to testing and small-scale production, laboratory extruders play a vital role. These compact machines are designed for research and development (R&D) purposes, allowing manufacturers to test new materials and processes before scaling up to full production. They are essential tools in industries that are constantly innovating, such as pharmaceuticals, packaging, and advanced materials. Laboratory extruders offer precision and control, enabling engineers and researchers to fine-tune processes and materials to meet specific requirements.

Recycling Extruders

With sustainability becoming an increasing priority, recycling extruders have gained significant importance in recent years. These machines are designed to process post-consumer or post-industrial plastic waste, transforming it back into usable material. Recycling extruders play a crucial role in reducing plastic waste, lowering production costs, and supporting circular economy initiatives. They are commonly used in industries focused on sustainable practices, where reclaimed plastic is reintegrated into new products without sacrificing quality.